High abrasion resistance is the characteristic property content of high level oxide manganese. Fabricated ceramic material has high level stand-up and other properties witch needed for use in hard conditions with minimum efficient of scale.

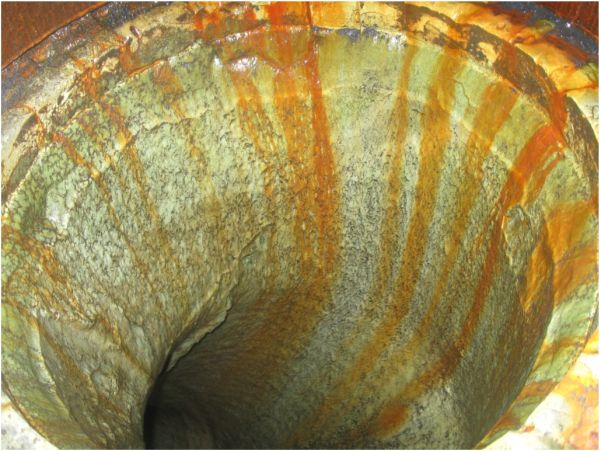

Monolith technology

- Body of iron construction is lining by amorphous prepared liquid melt

- Formation crystal constitution of needed length in process of inertial cooling and compressing

- Discharge of excess of melt

- Annealing and final layout of crystal monolith in thick walled pipe body

- Thickness of lining is choose a customer 50 -150 mm

- Possibility of reinforcement witch will be based on customer specification

- Possibility of welding

- Possibility of production heated lining pipe-systems

Dnipro lining plant Ltd. was organized in 2011 for commercialization and development of monolithic crystalline materials and ceramic constructions.

Strategic task of the company is radical cost reduction by using inexpensive heavy – wall monolithic thick walled pipe oxide-ceramic construction for mining.

Trademark: LMT pipes. ©

Lining production is organized on territory one of the iron foundry of «Nicopol ferroalloy plant» witch is the biggest manganese producer in Europe

In “Soviet time” was widespread development with participation of The National Academy of Sciences of Ukraine and leading expert centres for effective use manganese alloy slag in public household.

Since in early post-Soviet era this material base was stagnation. New stage of development was start in 2011 with foundation of our company and common strategy with management of «Nicopol ferroalloy plant». The fulfilment of these projects allow to improve production technology and sales satisfy customer requirements.

On the national business rating Dnipro lining plant Ltd. received official status “Industry leader 2014”, “Industry leader 2015”, “Exporter of Ukraine 2014”

Among Ukraine company’s it takes 6 place of export. 13 place in rating TOP-85 (gold) of Ukraine national rating “Leader Industry 2015“.

- 2 place in Top – 7 (Gold) 2013 -2014

- 3 place in nomination “Scale of production & solvency” 2013 – 2014

- 6 place in nomination “Social index” 2013 – 2014

- 2 place in nomination “ Investments attraction” 2013 – 2014

- 35 place in nomination “Authorized capital”2012 – 2013